In some workplaces, such as kitchens, laboratories, farms, milk industry, pharmacy, hospital, chemical plant, manufacturing, agriculture, food & beverage production, petrochemical industry or dangerous places such as construction, industry and mining, safety shoes are an indispensable protective equipment. Thus, we must pay attention to the storage of shoes after use, and never throw them aside. Safety shoes need to be stored and inspected correctly to extend the service life of the shoes. So, how to store safety shoes correctly?

To properly store safety shoes, you may consider the following methods:

Cleaning: Before storing, make sure to clean safety shoes to remove mud and other debris. When cleaning, use a mild soap solution to clean the boots. Avoid using chemical cleaners, which may attack the boot product.

Ventilation: Choose a well-ventilated place to store safety shoes to avoid moisture and mold growth.

Dustproof: You can use a shoe box or shoe rack to place safety shoes in a dry place to avoid dust adhesion.

Store separately: Store left and right shoes separately to avoid deformation and damage.

Avoid direct sunlight: Avoid exposing safety shoes to sunlight, which can cause the shoes to fade and harden.

Avoid contact with hot objects: Avoid contact of safety shoes with hot objects above 80℃

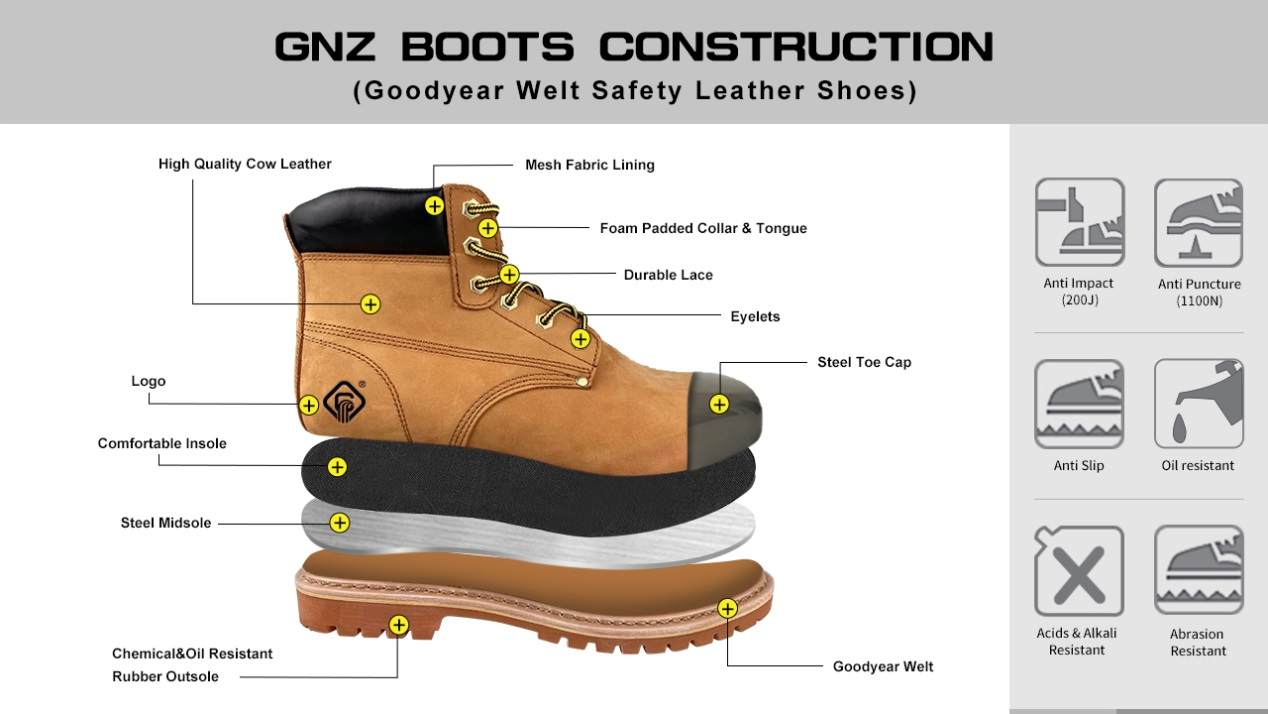

Check the steel toe and midsole: Safety shoes worn at work are often subject to wear and tear, so it is necessary to regularly check the wear of the steel toe and steel midsole and whether it is exposed to avoid the risk of falling or being injured due to excessive wear or exposure.

Proper storage not only extends the life of your safety shoes, it also helps keep workers safe and comfortable. Be sure to choose appropriate maintenance methods based on the material of the safety shoes and the environment in which they are used to ensure that the safety shoes are always in optimal condition.

Post time: Jan-08-2024